Why is Mould Flow Analysis for Mold Design Essential for Modern Manufacturing?

2025-08-26

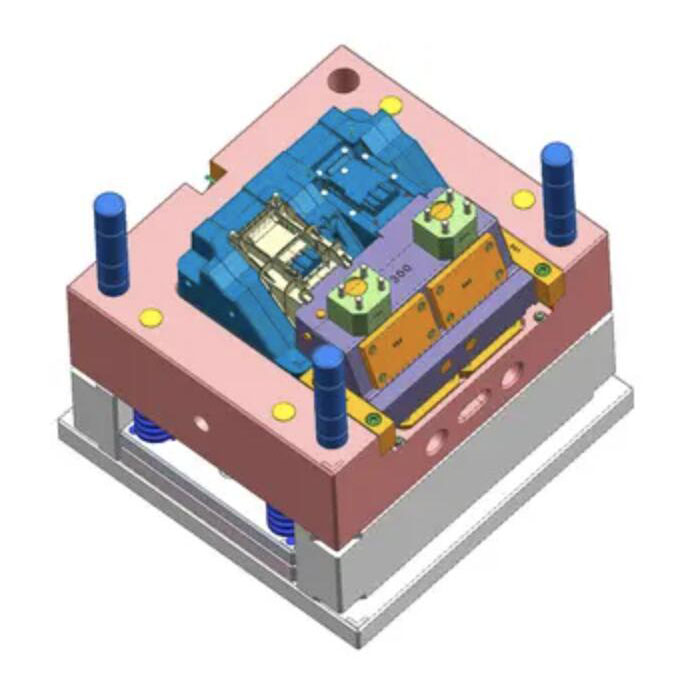

In the ever-evolving landscape of plastic injection molding, precision and efficiency are critical. One of the most powerful tools in achieving both is Mould Flow Analysis for Mold Design. This advanced simulation process helps engineers and manufacturers predict how molten plastic will flow inside a mold cavity before actual production. By doing so, it reduces risks, saves costs, and ensures high-quality product outcomes.

At Dongguan Xuan Pin Mould Technology Co., Ltd., we specialize in delivering high-performance mold solutions where Mould Flow Analysis plays a central role in ensuring accuracy and reliability for our clients worldwide.

Understanding the Role of Mould Flow Analysis

Mould Flow Analysis is a computer-aided engineering (CAE) simulation used during the mold design phase. It predicts potential defects such as air traps, weld lines, sink marks, or uneven filling. By running this analysis early, we can optimize gate locations, cooling channels, and cycle times, guaranteeing smooth and consistent production.

This process is not just about avoiding mistakes; it is about designing smarter molds with fewer revisions.

Technical Parameters of Our Mould Flow Analysis

At Dongguan Xuan Pin Mould Technology Co., Ltd., our team leverages advanced simulation software and years of engineering experience. Below are the core technical parameters we focus on during Mould Flow Analysis for Mold Design:

Key Features and Benefits

-

Filling Simulation – Tracks plastic flow front to detect imbalance or short shots.

-

Packing & Holding Analysis – Ensures uniform pressure to minimize shrinkage and warpage.

-

Cooling Optimization – Designs effective cooling circuits for cycle time reduction.

-

Warpage Prediction – Prevents deformation and dimensional inaccuracy.

-

Fiber Orientation & Material Behavior – Analyzes composite material performance.

Technical Table: Parameters We Deliver

| Parameter | Description | Value/Capability |

|---|---|---|

| Flow Pattern Prediction | Simulates flow front, weld lines, and air traps | Up to 99% accuracy |

| Cooling Time Optimization | Determines cooling circuit efficiency | Reduction of cycle time by 15% |

| Pressure Distribution | Evaluates packing and holding pressure across cavities | Uniform within ±3% |

| Warpage Control | Predicts dimensional distortion | Deviation <0.1mm |

| Material Data Library | Wide range of thermoplastics and reinforced composites | Over 5,000 materials supported |

| Cycle Time Reduction | Balanced filling and cooling design | 10–20% faster cycle efficiency |

FAQ – Mould Flow Analysis for Mold Design

Q1: What is the main purpose of Mould Flow Analysis for Mold Design?

A1: The primary purpose is to simulate how plastic flows within the mold cavity, predicting potential defects such as air traps, weld lines, or sink marks. This allows engineers to adjust mold design before physical production, ensuring higher product quality, reduced costs, and faster development cycles.

Q2: How does Mould Flow Analysis reduce manufacturing costs?

A2: By identifying design flaws early, Mould Flow Analysis minimizes the need for physical prototyping and mold rework. This prevents wasted materials, reduces production downtime, and accelerates time-to-market. The overall effect is significant cost savings during the product lifecycle.

Q3: Is Mould Flow Analysis suitable for all industries?

A3: Yes, it is widely used across industries such as automotive, aerospace, electronics, medical devices, and consumer products. Any project requiring high-precision plastic parts benefits from Mould Flow Analysis, making it a universal solution for mold designers and manufacturers.

Advantages of Partnering with Dongguan Xuan Pin Mould Technology Co., Ltd.

Choosing the right partner is just as important as the technology itself. At Dongguan Xuan Pin Mould Technology Co., Ltd., we offer:

-

Comprehensive support from design to final production.

-

High-precision mold design backed by 10 years of expertise.

-

Global clientele with proven track records in demanding industries.

-

Cutting-edge engineering tools for Mould Flow Analysis.

-

Reliable customer service that ensures long-term satisfaction.

We believe that trust, innovation, and technical excellence are the pillars of successful cooperation.

Conclusion: Driving Success with Mould Flow Analysis

In today's competitive manufacturing environment, Mould Flow Analysis for Mold Design is no longer optional—it is essential. By integrating this process into the early stages of mold design, manufacturers achieve higher accuracy, reduced costs, and optimized production efficiency.

If you are looking for a professional partner with proven expertise, Dongguan Xuan Pin Mould Technology Co., Ltd. is ready to support your next project with advanced Mould Flow Analysis and precision mold design services.

Contact us today to discuss your project needs and discover how we can help you succeed.